From sports to fashion, including schoolbags, Polyester 600D is an essential fabric when addressing the bag industry :

it is easily available and popular for its sturdiness and reasonable price.

That is why, Polyester 600D, with PU coating or PVC backing,

is the material selected the most often when it comes to manufacturing bags and luggage.

When you pick a 600D, do you always know exactly what you are buying?

600D Polyester is now a "basic" fabric that is offered by virtually all weavers and manufacturers.

Many different grades are presented under the same generic name of “600D”.

That is how you may find price gaps up to 50% between different suppliers, for apparently the same fabric.

How to explain these price differences for a "same" 600D fabric?

Thread variation : smaller Deniers. Oddly enough, it is nowadays seldom to get a 600D weaved with 600 Deniers thread...

Instead the following thread weights are commonly used: 400D, 500D, 450D, 600DX300D and even 300DX250D..... Of course, the smaller the thread, the lower the price of the finished fabric.

Weaving density (or thread count) variation. Six different densities can be used to weave “Polyester 600D”: from the loosest 64T to the densest 84T.

If using the same thread, you will obviously buy a 64T dense fabric cheaper than a 80T one: it requires less thread and is woven faster....

How to choose THE polyester 600D grade that suits you?

Beyond cost considerations, thread thickness and density of fabrics directly affect the functional and aesthetic performances of your finished product.

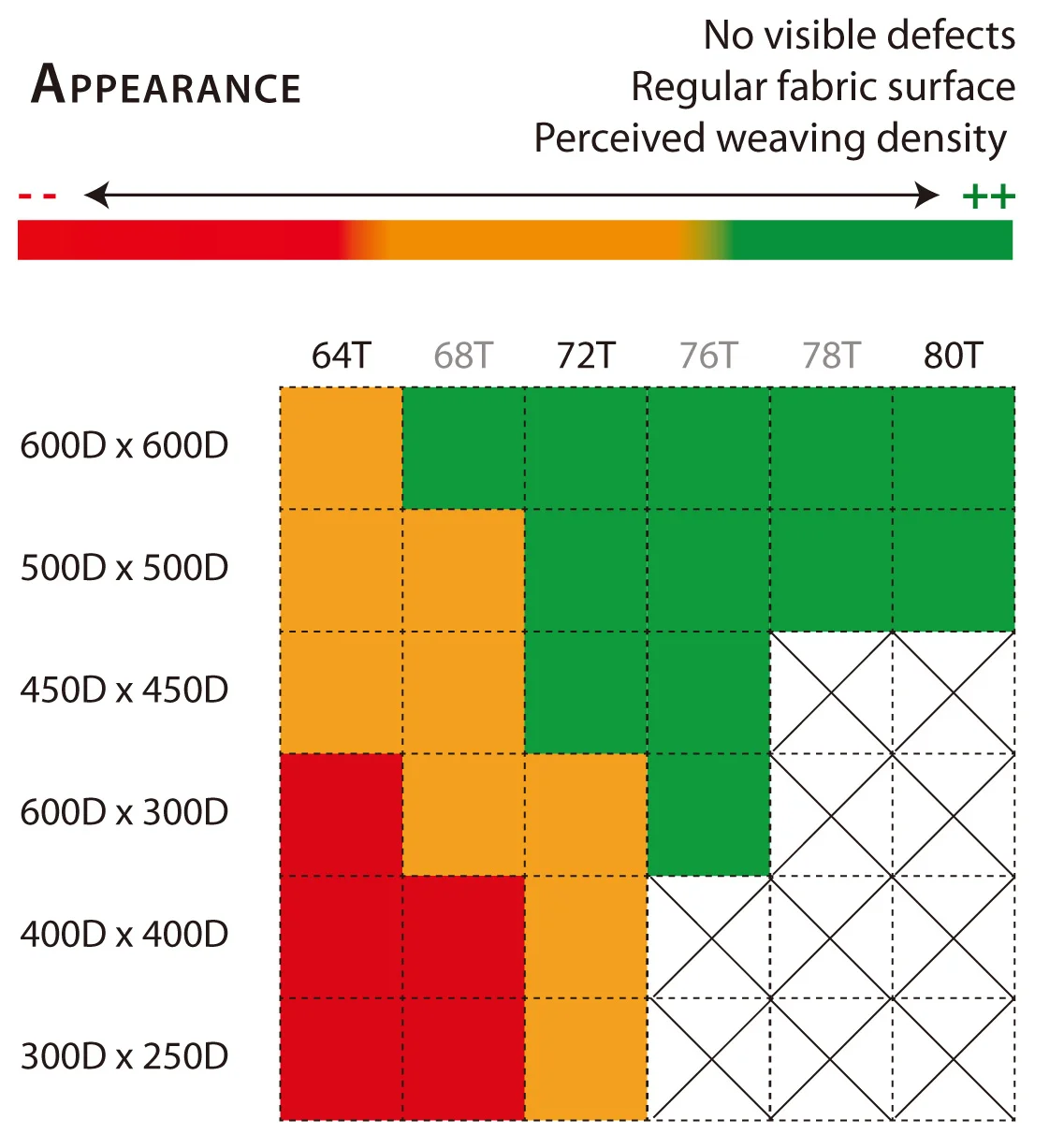

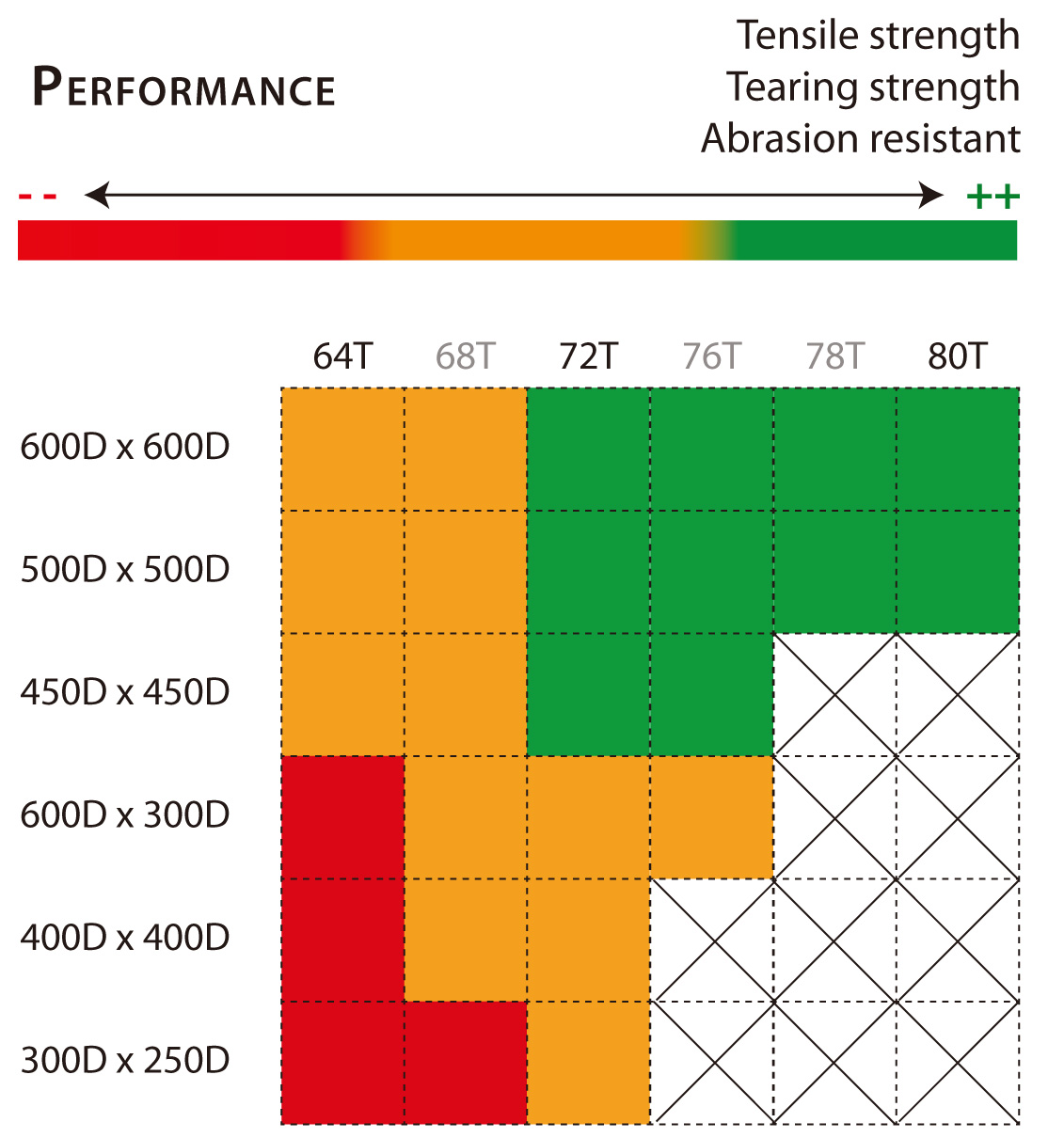

You should consider thoroughly what each grade of 600D can deliver as to :

The mechanical performance of the fabric: resistance to tearing, tensile strength, abrasion resistance. The lifetime of your product is directly proportional to these values.

The general appearance of the fabric (drawn yarn, visible density, thickness and hand feel) changes with its technical attributes (titration-density).

Low density and/or thin thread mean more defects on the surface of the fabric and a poor hand feel which affect:

o The perceived quality of your product in the eye of the end customer

o The cost of your product as it will then have to incorporate a higher scrap rate at cutting stage (panels with defects will have to be discarded) and a higher labor cost (the cost of time spent to sort the acceptable panels from the defective ones)

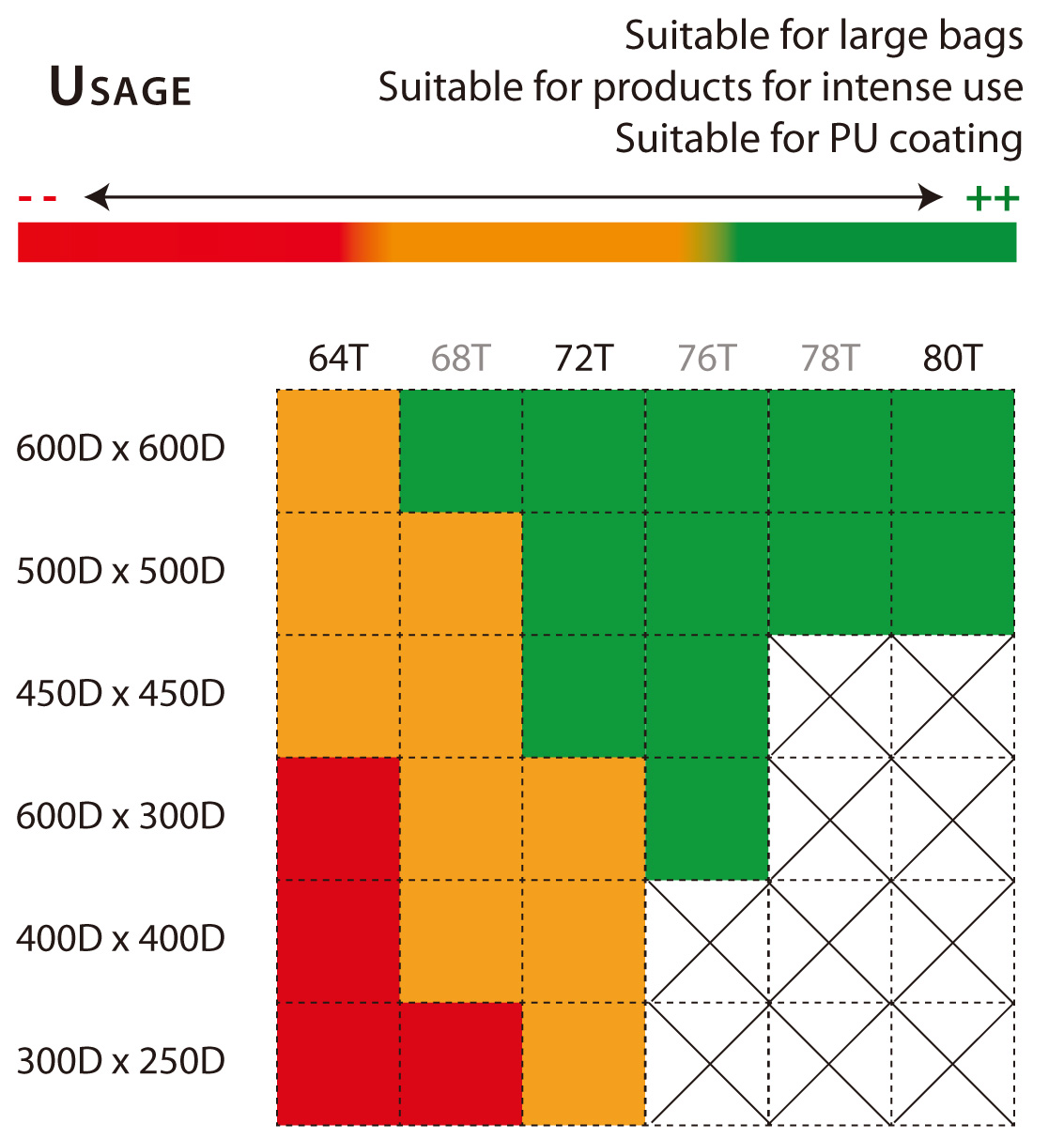

Whether or not PU coating (polyurethane) is suitable on this fabric.

PU coating is a thin layer of polyurethane which role is to keep woven thread together and seal the finished fabric, it also adds to the waterproof performance of the material.

If the fabric density is too low, this liquid PU extends through the fabric and stains the surface.

Moreover, a fabric with loose weaving remains too weak for bigger bags if only backed with a thin layer of PU.

If you do have to back your fabric with PVC because it is too loose or too thin this is what you will have to take into consideration :

o the cost of your product (PVC backing is more expensive than PU coating),

o whether it has to comply with regulations such as the REACH regulation ( a “regular” PVC backing is not REACH compliant, this has to be expressly required when you place your order)

o its weight (a PVC backed fabric is two times as heavy as the same fabric with PU coating)

As a result, you should carefully pick the quality of your polyester 600D according to :

your final product’s look

how it is supposed to perform

Your target price

Generally speaking, Heavy duty bags must be made with denser materials and heavier threads if they are expected to last in time.

These may be products intended to carry heavy loads (Tool bags for example), which are subjected to repetitive pulls (e.g. handles of travel bags or backpack straps), or which will be subjected to a daily use (e.g. satchels).

The below three tables give summary indications of performance and possible applications for different grades of polyester 600D which may help you to pick the best cost/performance ratio for your product.

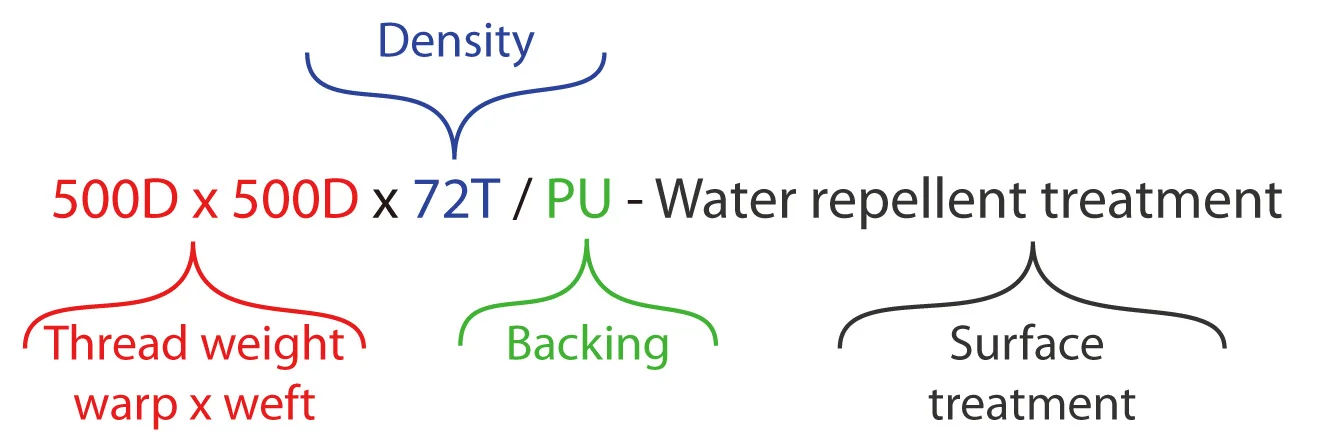

How to identify the quality of your 600D?

The easiest way is to ask for the complete characteristics of your chosen fabric to your supplier : deniers of the thread, weaving density and treatments-water resistant treatment, coating, etc...).

Abbreviations are often used when talking about fabrics, however, before confirming your choice, it is recommended that a more complete name of the fabric is communicated to you.

The minimum pieces of information that must be indicated to you are as follows:

“Composition .......D x ........D x ........T / backing --- Surface finish”

Example : “Polyester 500D x 500D x 64T / PU – water resistant treatment”

Here you will find here two crucial pieces of information to evaluate the quality of your 600D:

thread weight (Deniers) used on warp and weft

weaving density

2. The "hands-on" approach : take your thread count glass and validate by yourself the density of the weaving, compare the denier of the thread to an existing standard denier.

Attention : the thickness of the finished fabric is not a reliable way to validate the quality of a material. Indeed, a thin fabric can end up as a reasonably thick finished material as layers of PU or PVC can be added for that purpose.

Tearing and tensile strength of a material (which are the backbone of a bag’s sturdiness) are primarily correlated to the quality of the woven fabric without coating. PU or PVC backings are here only to boost this performance.

To sum up :

A fabric with a very attractive price is not necessarily a good deal: in the case of Polyester 600D it usually reflects a lesser quality.

It is advisable to systematically request the complete specifications of your fabrics from your suppliers: you will be able to carry out more efficient negotiations with them, anticipate the percentage of waste if there were to be some and most importantly, ensure that the finished manufactured product will meet your expectations.

In any case, it is safer and reassuring to perform simple tensile strength tests when a new material is used. In this way you will avoid setbacks and unnecessary problems during production.

Buy smartly by picking the density/thread weight 600D that shows the best cost/performance ratio for your product : it is not necessary to choose a fabric that will over perform and weigh on your price, it is however safe to understand what performance and looks can be expected with cheaper density/thread weight combinations.

You may check here the 600D material that we offer, showing their technical specifications :

Plan ahead ! Download the China Holidays calendar for 2023